Osha Chemical Storage Inspection Checklist

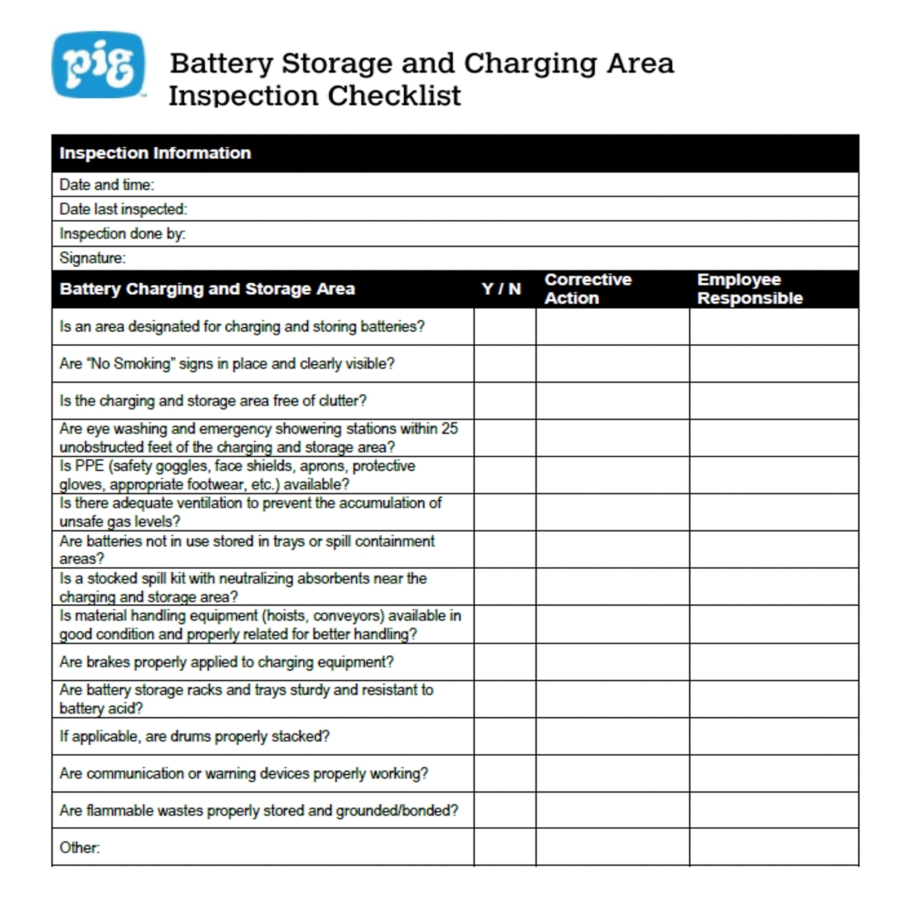

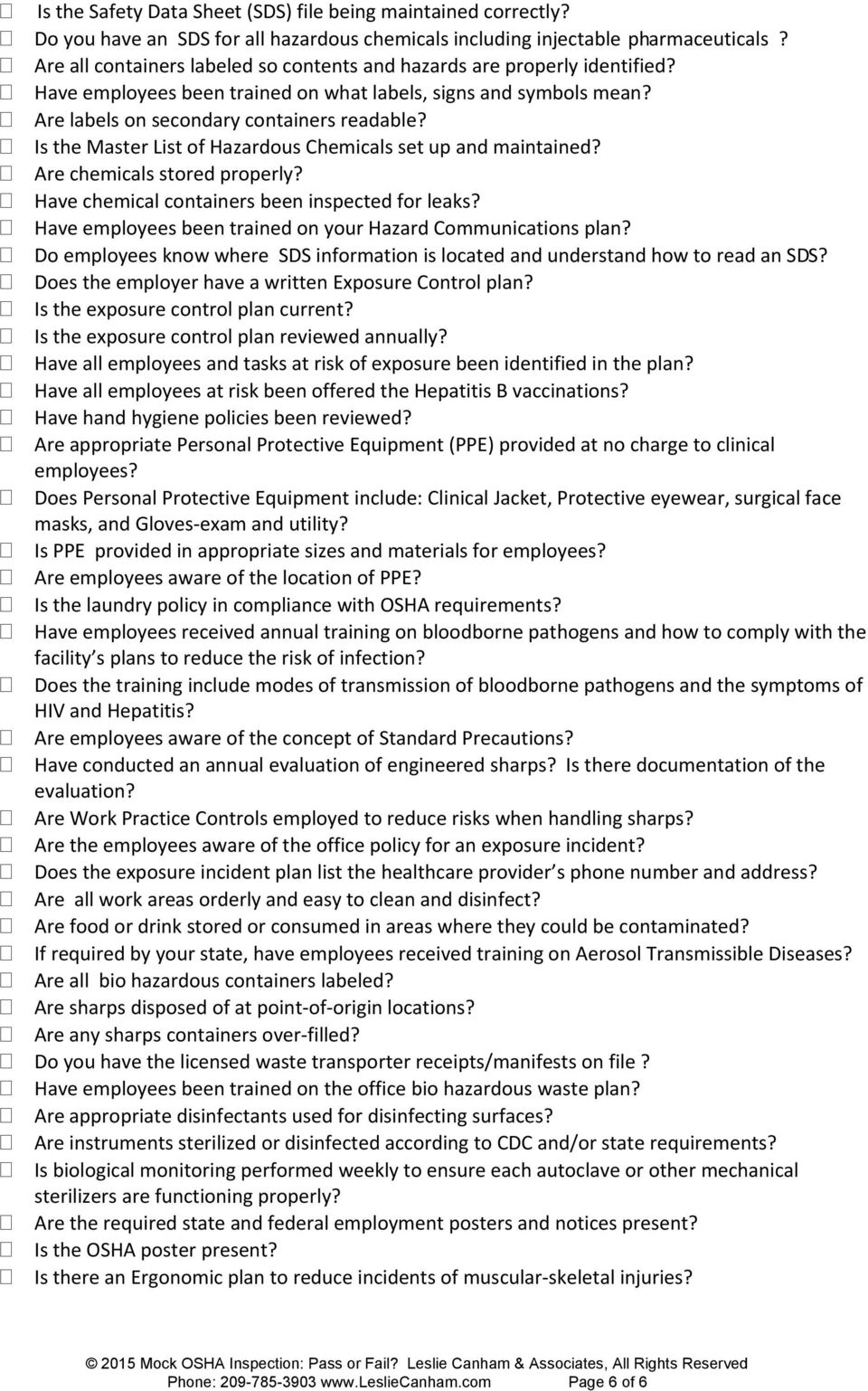

All approved chemical storage rooms and fire rated cabinets shall be inspected monthly.

Osha chemical storage inspection checklist. Ensure that trained and fully equipped personnel will be performing the task. Storage handling transportation spills disposal amounts used toxicity or other. Begin your inspection by checking the integrity of individual safety cabinets. One way to help understand a given situation is to look at it on a periodic basis.

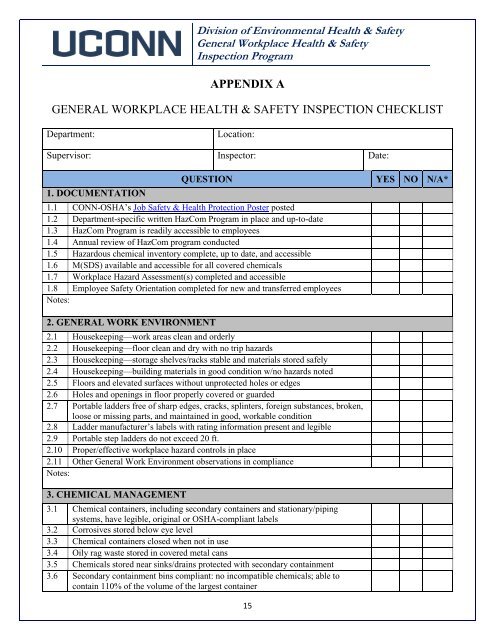

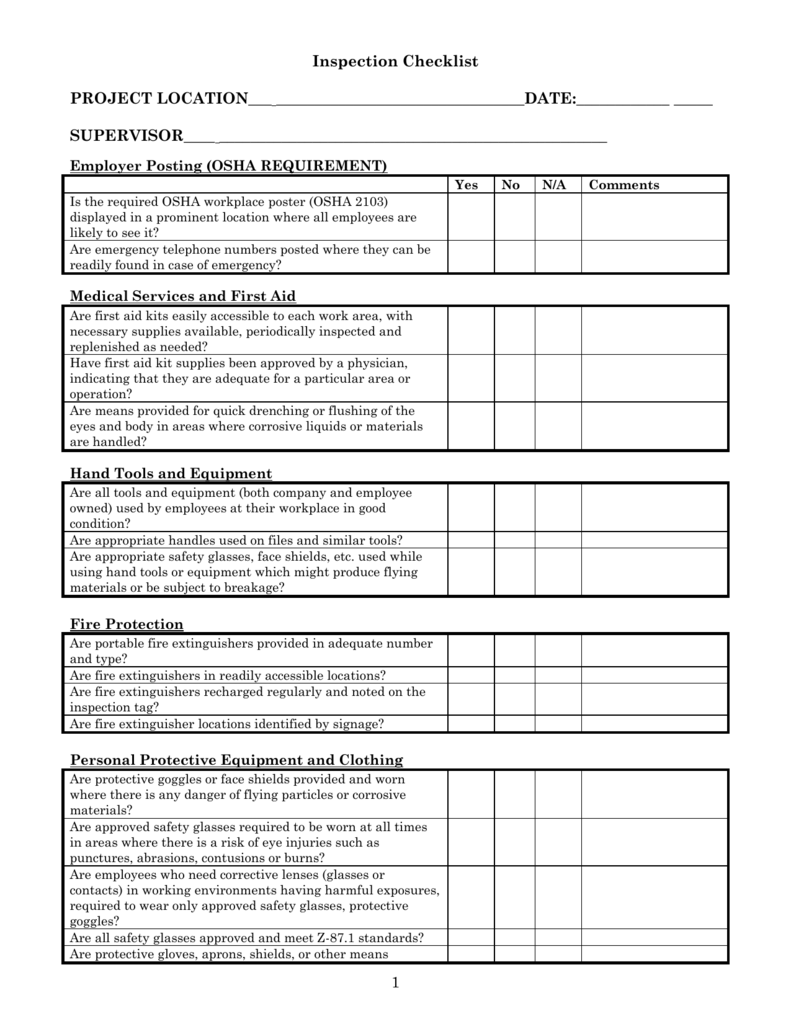

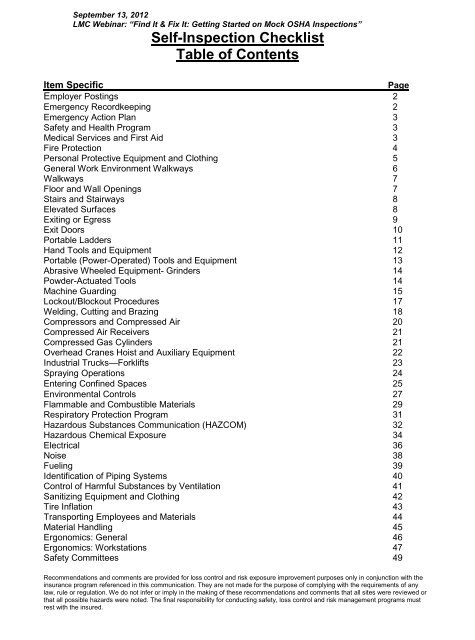

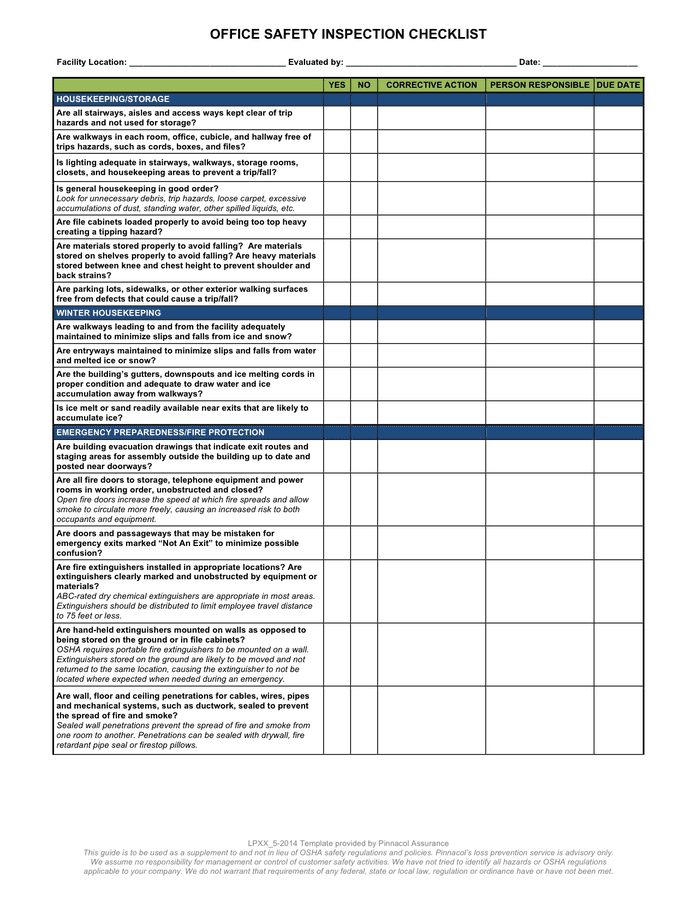

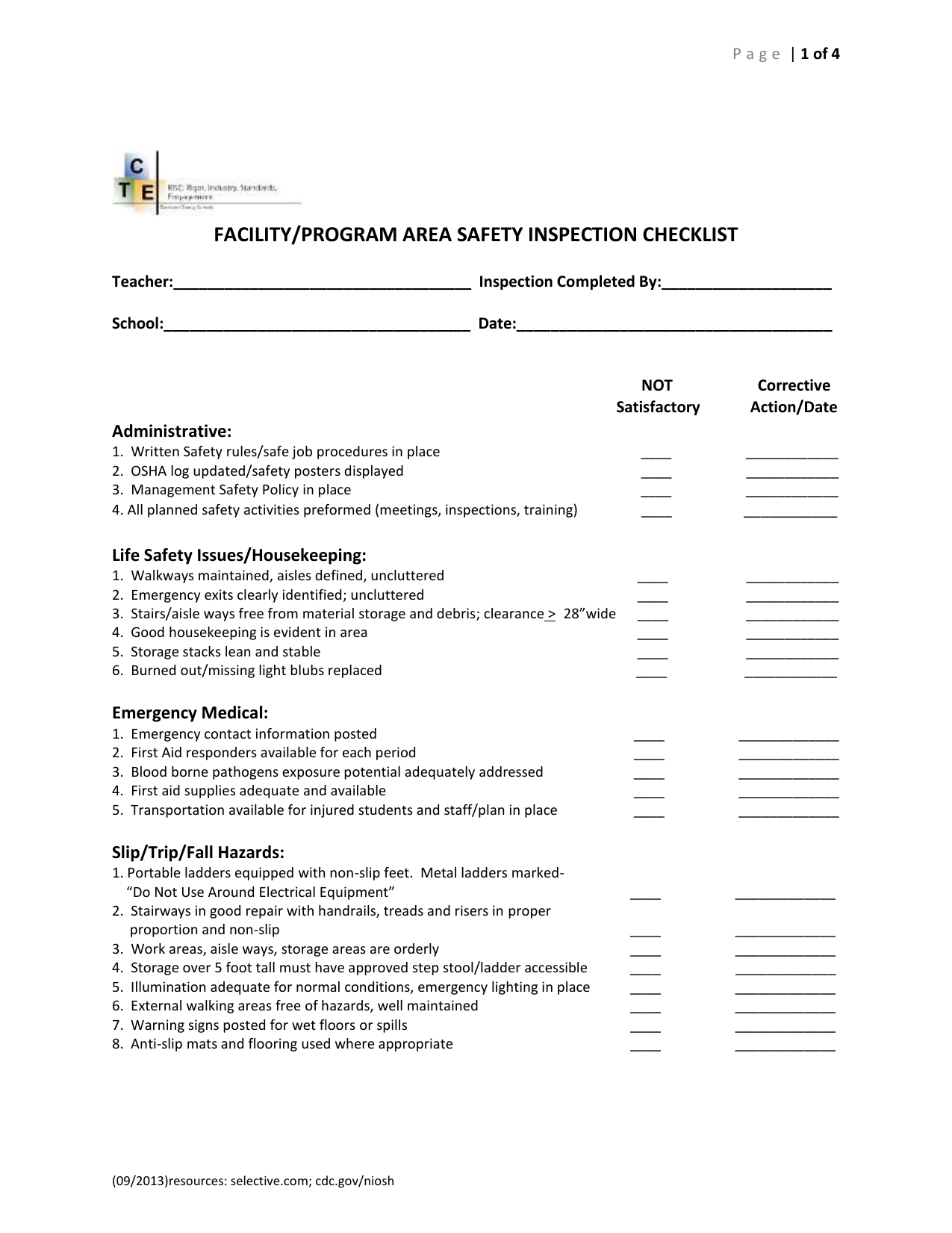

22 ÿ is housekeeping maintained. This document contains twenty two safety inspection checklists designed to help you evaluate your work areas. 36 37 ÿ are exits properly marked. Design and maintenance yes no n a location and design of chemical storage rooms and cabinets approved by physical plant and safety office doors locked when room unoccupied access limited to authorized personnel.

22 ÿ width of aisles maintained. E maintains inspection personnel training and inventory records. All storage facilities that do not fit under one of these exemptions should determine whether they fall under the osha psm standard and comply with the standard if they do. C monitors procurement use storage and disposal of chemicals.

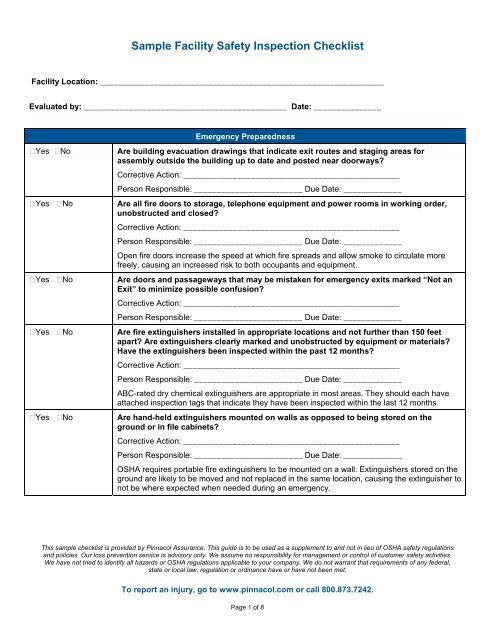

The specific needs practices form of government and other operational procedures of your governmental entity may impact whether this example is appropriate for your use. 36 37 ÿ any emergency power supply. Storage facilities typically have considerably less complex process safety issues than facilities with large chemical manufacturing operations which may make compliance easier. This osha hazardous chemical exposure self inspection checklist can be used as a safety precaution before handling chemical substances.

Are all containers free from leaking or corrosion. D conducts regular inspections of the laboratories preparations rooms and chemical storage rooms and submits detailed laboratory inspection reports to administration. Safety compliance checklist chemical storage house keeping 29 cfr 1910 ÿ are aisles marked. 22 exits ÿ are building exits adequate.

Safety and osha inspection checklists the most widely accepted means to identify workplace hazards is to conduct safety and health audits. 22 ÿ are aisles in good condition. Are there no structural defects. 36 37 ÿ does lighting in hallways and exit.

Sample flammable liquid storage inspection checklist page 1 of 2 disclaimer. We recommend carrying out regular inspections on your chemical stores and have supporting procedures in place so workers know how to respond to a safety breach and take immediate corrective actions. Your checklist should include. Chemical storage area daily safety checklist.

Are staff familiar with the location and proper use of all safety equipment. Is a spill clean up kit available and replenished. 22 ÿ are work areas clean. Osha hazardous chemical exposure checklist.