Pallet Racking Audit Template

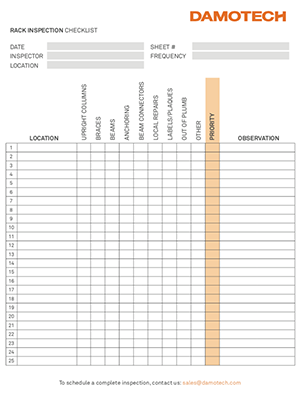

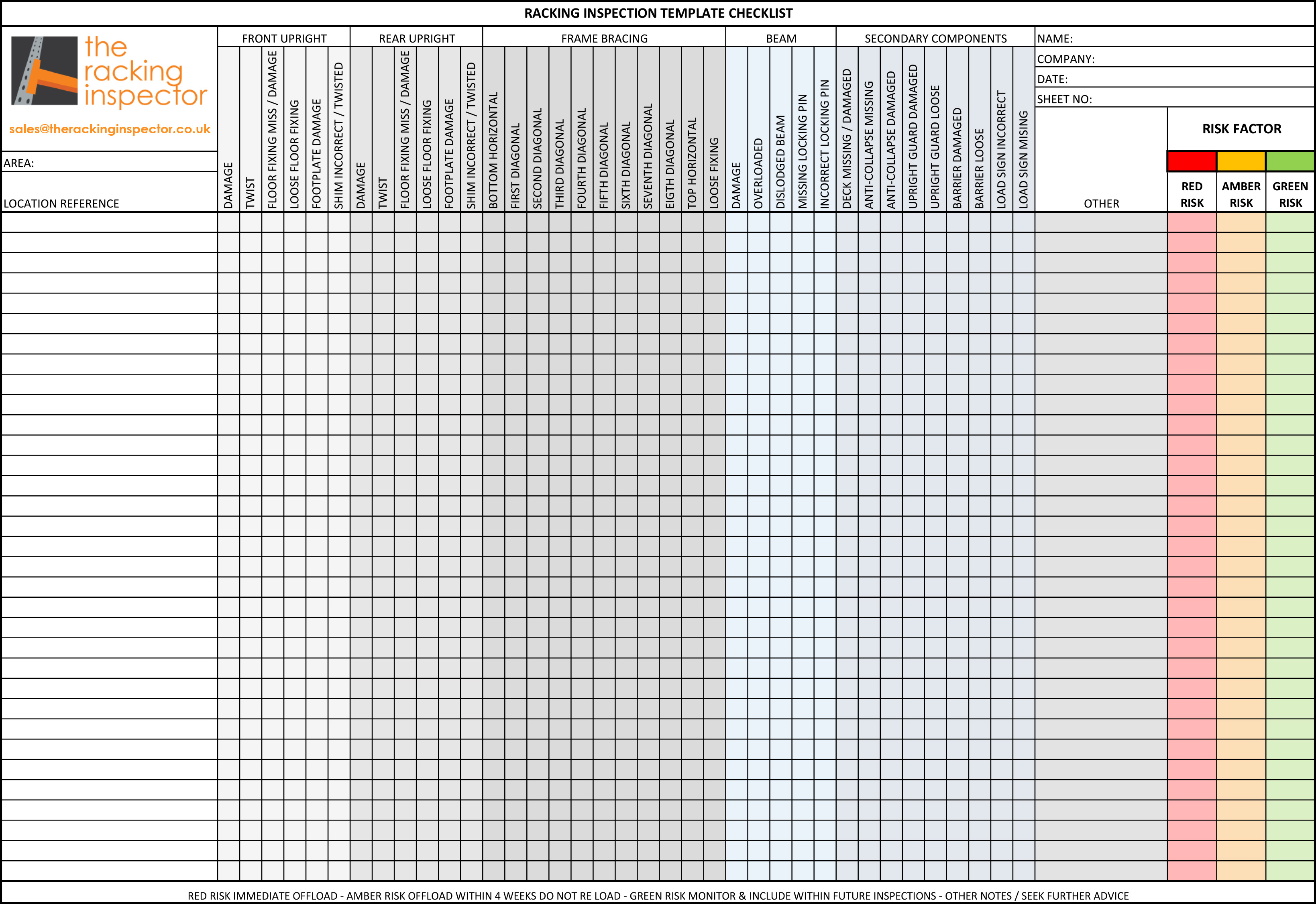

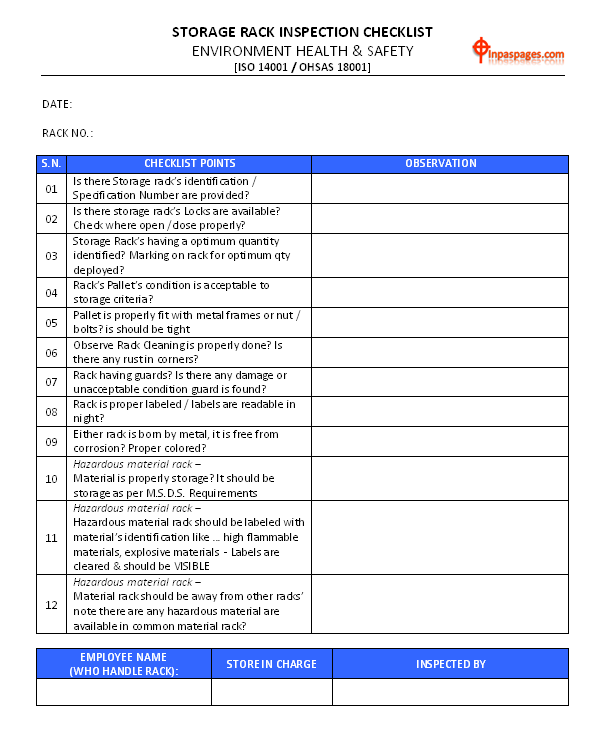

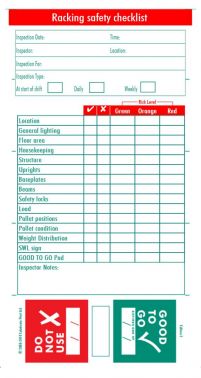

This pallet racking inspection checklist includes pallet specifications rack components damage guidelines and risk assessment based on the traffic light system.

Pallet racking audit template. Living on our shaky isles means earthquakes are relatively common. Regular racking inspections can save you tens of thousands of dollars in potential damages and inventory loss and can even save lives. Racking inspection damage report about the template. Under the australian standards for steel storage racking as4084.

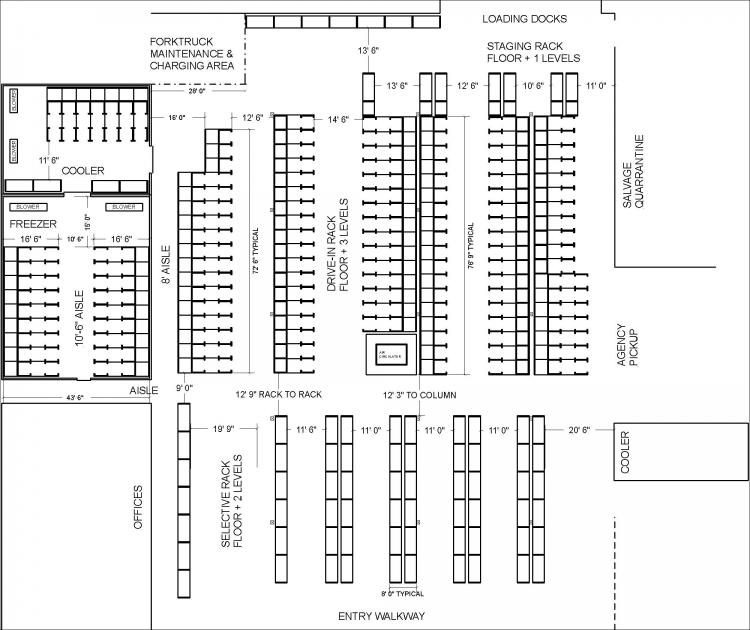

A qualified engineer can be booked to visit your work site to inspect compile a report make recommendations to improve repair. A pallet racking audit is a thorough inspection and evaluation of the condition of the pallet racking in order to identify any damage to the system that may be causing a risk to safety. This checklist does not cover every aspect of pallet racking inspections and it is the responsibility of the person s carrying out the inspection to be aware of. Every warehouse has its own unique mix of available storage space products distribution rates and strategies.

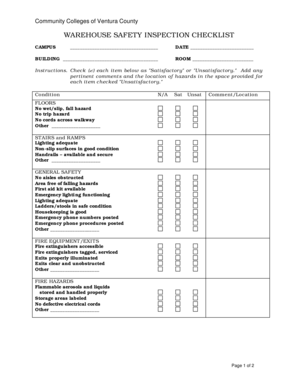

It is good working practice to undertake local racking inspections through trained competent personnel although pallet rack inspections are a statutory requirement under health and safety legislation. In order to design a pallet racking system for your company s needs that also maximizes efficiency begin by considering three factors unit method and area. The typical unit being stored on pallet rack is a load of product sitting on a pallet. To ensure the ongoing safety of your staff and your stock we highly recommend a programme of maintenance and safety audits.

Pallet racking audits pallet racking frames and beams can suffer impact damage from forklifts. He is an experienced sema approved racking inspector who works diligently and methodically. Keeping your pallet racking installation in good working condition is essential for safe operation and a long life. Our racking inspection training course is run by one of the few sema approved racking inspectors to be a sema approved pallet racking inspector and a sema approved cantilever racking inspector.

This pallet racking inspection checklist is for general guidance and should be used only by trained and qualified racking inspectors. A safety audit is a good way to keep your racking safe complying with australian oh s standards. A pallet racking inspection is a systematic process to ascertain that warehouse pallet racks are in good working condition. We have used chris for quite some time now on both small and large scale pallet racking inspections and found his work to be excellent.

Our course can be delivered at our easily accessible centre which is near london or at your business.