Pallet Racking Inspection Checklist Australia

The work health and safety legislation requires that plant and structures including racking are without risks to health and safety.

Pallet racking inspection checklist australia. In fact according to australian standards 4084 2012 pallet racking inspections are to be conducted every 12 months by a competent person. When doing inspections consider the following. File type and size. The whs legislation requires that plant and structures including racking are without risks to health and safety.

A safety audit is a good way to keep your racking safe complying with australian oh s standards. This pallet racking inspection checklist is for general guidance and should be used only by trained and qualified racking inspectors. We specialise in rack safety inspections and audits keeping your work place safe. Pallet racking inspection checklist.

Keeping your pallet racking installation in good working condition is essential for safe operation and a long life. Clearly stated in the australian standards is the need for an annual safety rack inspection. This checklist does not cover every aspect of pallet racking inspections and it is the responsibility of the person s carrying out the inspection to be aware of. Even if you hire a professional to conduct an annual inspection of your pallet racking system it is recommended that you check your pallet racking system for signs of damage between audits.

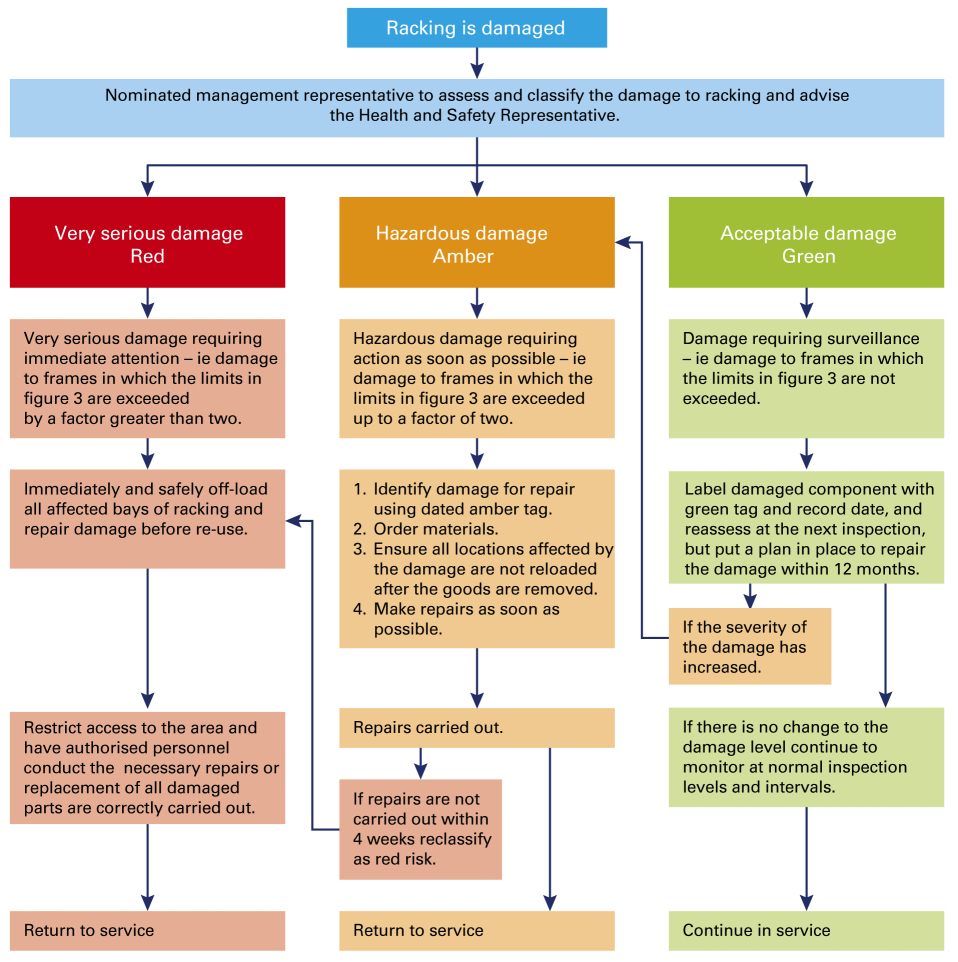

This pallet racking inspection checklist includes pallet specifications rack components damage guidelines and risk assessment based on the traffic light system. Pallet racking operation and maintenance how to reduce or eliminate the workplace health and safety risks in warehouses and storage by correctly operating and maintaining pallet racking. The end user guide to pallet racking inspections. A pallet racking inspection is a systematic process to ascertain that warehouse pallet racks are in good working condition.

Pallet racking inspection checklist. Pallet racking inspections should be conducted regularly in order to prevent accidents caused by structural damage as well as to ensure that your racking system is in compliance with the standards. The following is a list of areas to check for potential problems in a pallet racking system. Rack inspect can carry out your annual pallet racking safety and compliancy inspections as per whs requirements.

Weekly pallet racking inspection checklist racking inspections shall be carried out on a regular basis and at least every twelve months. This course is designed to make your person responsible for rack safety prrs competent to enable them to assess damage of all components within the racking structure and how each component works in making it safe during operations. To ensure this racking should be inspected regularly to confirm its integrity.