Pallet Racking Inspection Form

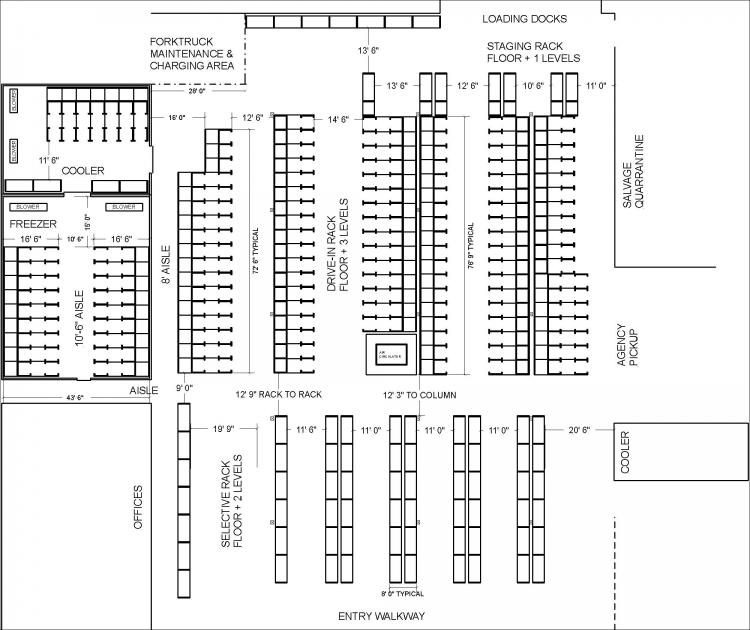

If you have new racking installed or make significant layout changes then you should have it tested.

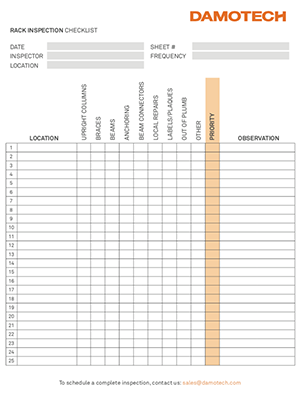

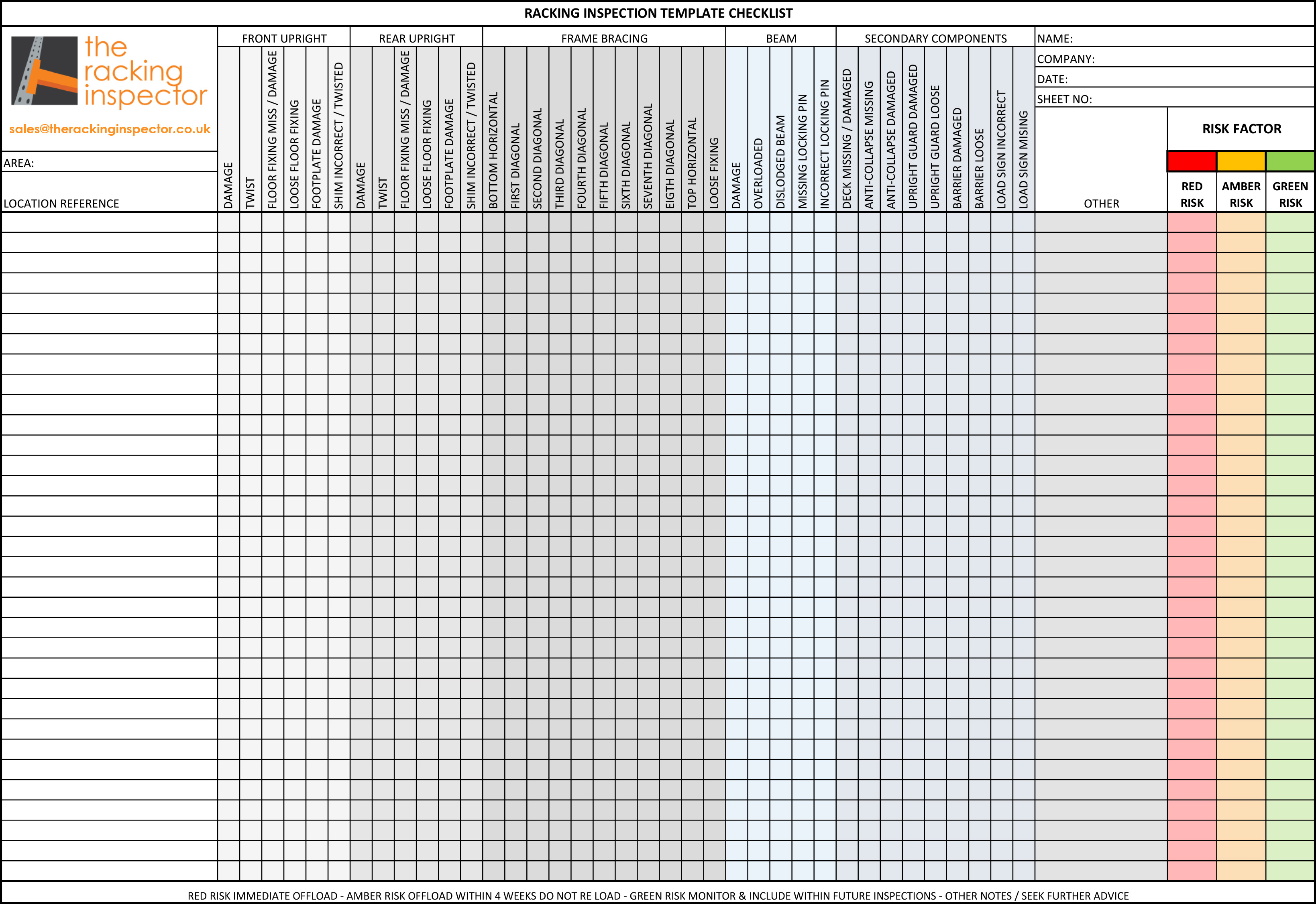

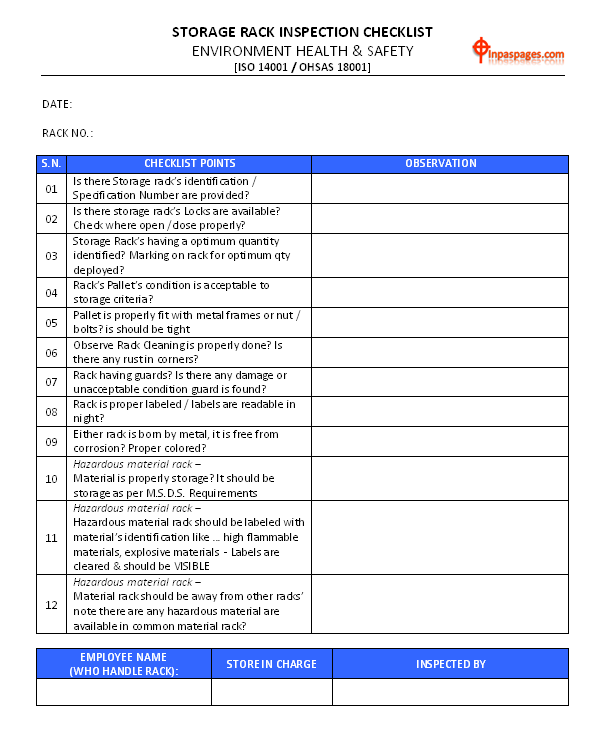

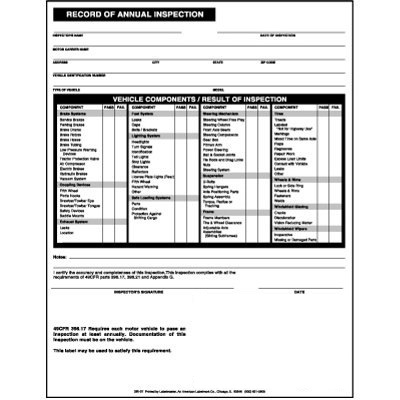

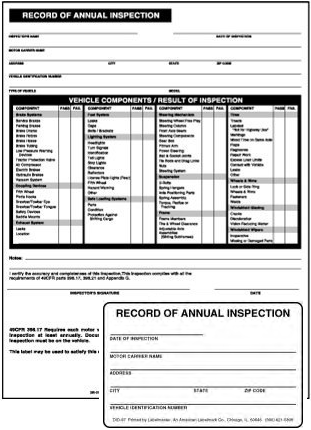

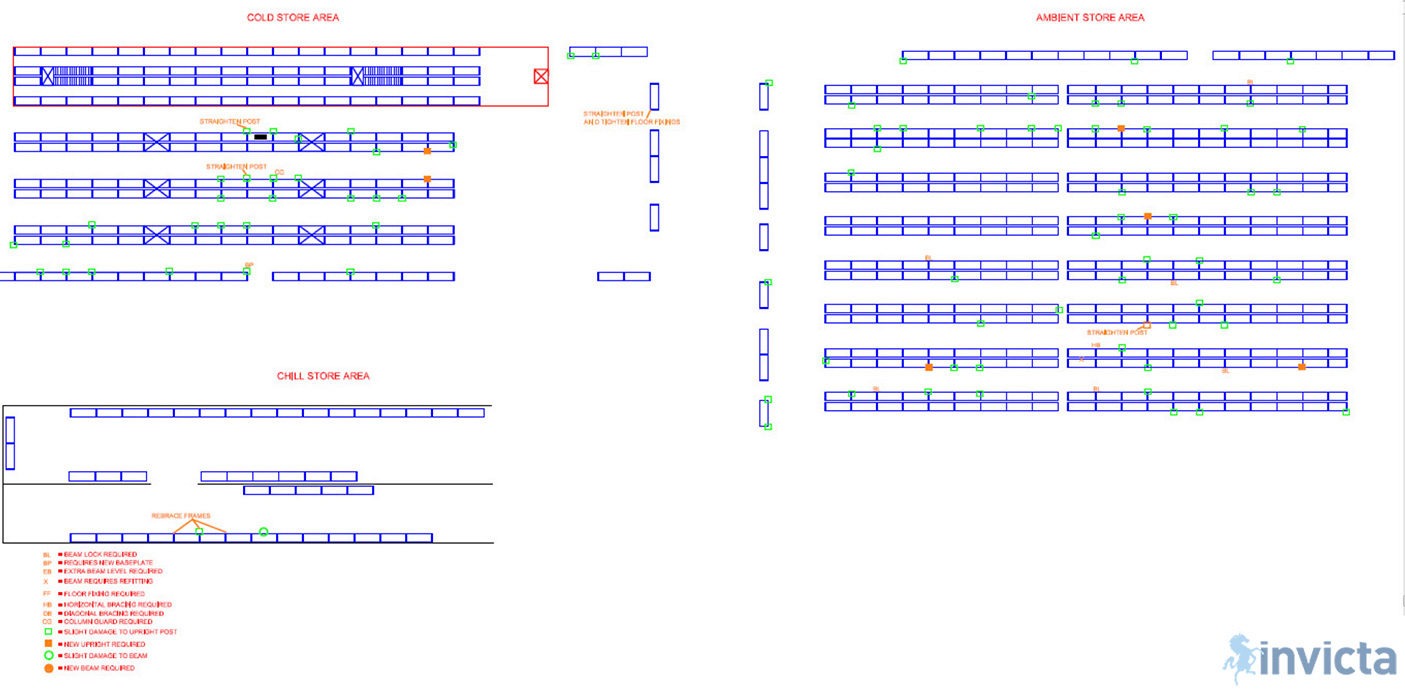

Pallet racking inspection form. Pallet rack inspection checklist employers can use this checklist to help ensure their pallet racks are inspected by a qualified person as per the new storage rack requirements of section 4 43 1 of the occupational health and safety regulation effective january 1 2018. Pallet racking inspection checklist. A pallet racking inspection is a systematic process to ascertain that warehouse pallet racks are in good working condition. We will be using the racking inspector annually going forward.

The design of the pallet should take into account the nature of the goods in the unit load. Make racking inspections a priority in your workplace by ensuring your annual check is completed on time. Goods on pallet to be stored in racking. The racking inspector carried out an annual inspection on our warehouse racking system and was very knowledgeable very helpful and informative with useful tips to help us maintain a safe and compliant racking system.

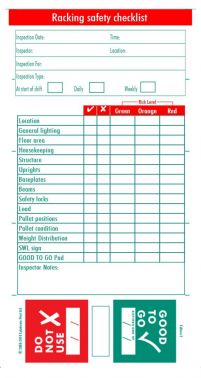

Goods stored on pallets destined for storage are termed unit loads. Pallet racking safety guidelines are vital in keeping your workplace safe and secure as detailed in hse racking inspection legislation. A change in the pallet design should not be permitted unless the. This pallet racking inspection checklist includes pallet specifications rack components damage guidelines and risk assessment based on the traffic light system.

This pallet racking inspection checklist is for general guidance and should be used only by trained and qualified racking inspectors. In addition hsg76 sema storage equipment manufacturers association guidelines stipulate that you must appoint a person responsible for rack. Also to ensure the racking is still in a condition that is acceptable to australian standards. The employer should establish and implement a program of regularly scheduled storage rack system inspections.

This checklist does not cover every aspect of pallet racking inspections and it is the responsibility of the person s carrying out the inspection to be aware of. A weekly safety inspection by an operations manager will keep on top of any damage that has occurred to the racking structure that may have gone unreported. Pallet racking is classed as work equipment under puwer requires regular inspection. Beams and cross bars do a lot of the work when it comes to supporting the load on pallet racks and as such they need frequent inspection and replacement.

Hsg76 is the health safety executive guide to warehousing storage and clearly sets out the need for and type of racking inspections required in a warehouse. The inspections should be performed by a qualified person familiar with the storage rack design and installation requirements retained or employed by the storage rack system owner.