Pallet Racking Maintenance Checklist

Warehouse maintenance checklist.

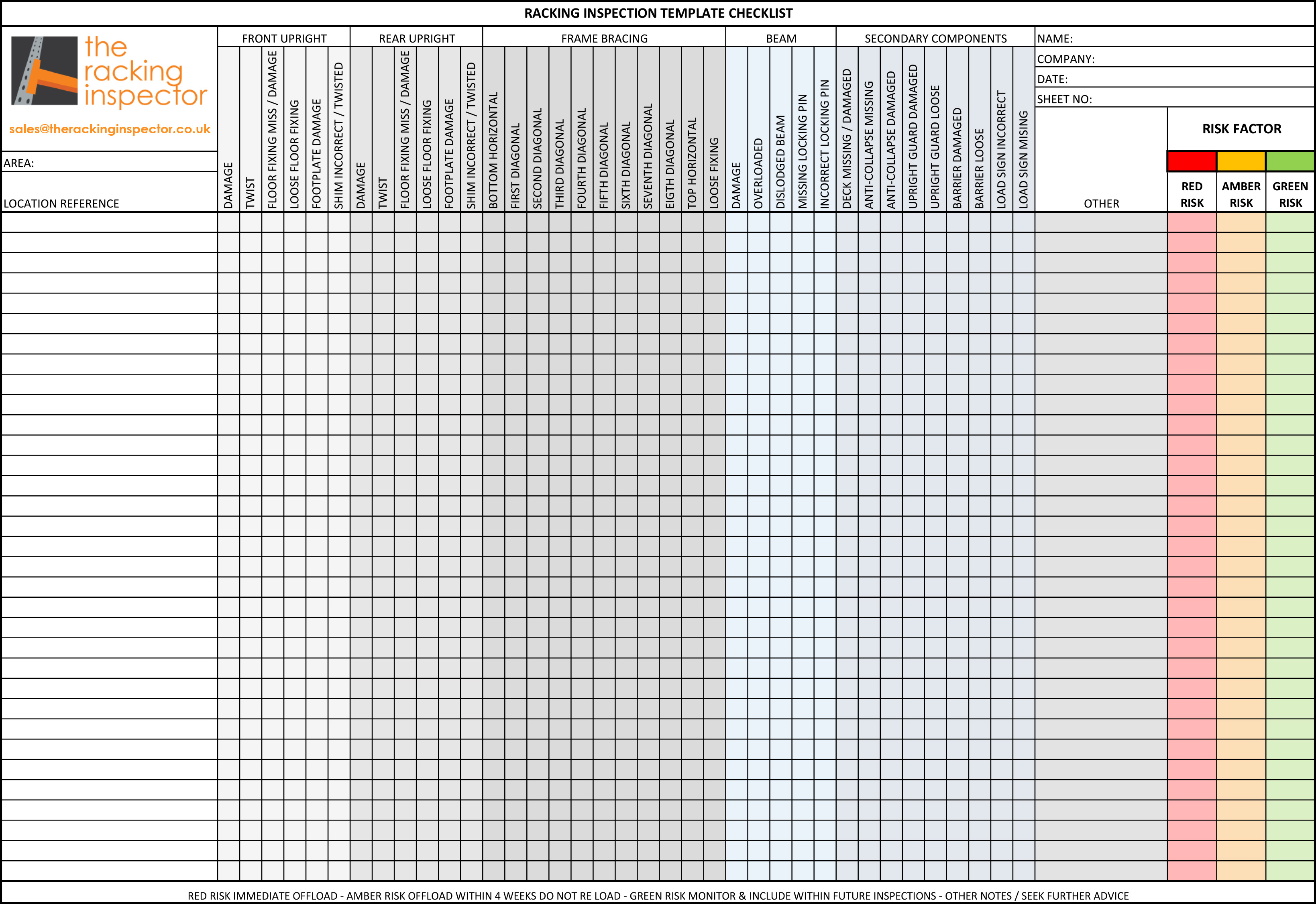

Pallet racking maintenance checklist. Review for any twisting of the frame column. Dent on face of beam bent permanently flange damage top or bottom beam connector improper. Any front and back footplates which. Any rips tears beyond the manufacturer limits need to be repaired or replaced.

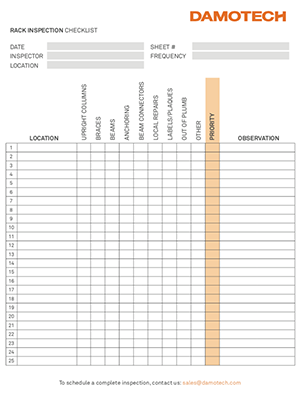

Racking inspections shall be carried out on a regular basis and at least every twelve months. Diagonal brace missing damage horizontal brace missing damage. Pallet rack maintenance frame inspection. In doing this you are also protecting your staff from injury.

Check for broken welds. Inspect for any bent or missing horizontals and diagonals. Steel storage pallet racking inspection checklist. Check the front and rear column of each upright for any damage due to pallet loading or forklifts.

Our pallet racking systems help keep your warehouse neat and tidy as well as safely storing your products. Any beam with visible deformation or cracking of the beam end connectors should be unloaded and replaced. Weekly pallet racking inspection checklist. A rack inspection check the storage system for damage.

Perform efficient racking inspections on a mobile device gather photo evidence of damaged warehouse racks create traffic light system based actions with colleagues or superiors automatically generate and share reports as you complete an inspection. How to reduce or eliminate the workplace health and safety risks in warehouses and storage by correctly operating and maintaining pallet racking. For quality comprehensive racking audits at a competitive price contact macrack on 1800 048 821. Direct we want you to make the most out of your warehouse and the only way that you can do that is through regular maintenance and care.

Post column damage. Bracing horizontals diagonals. Check all load bearing beams under the shelves and cross bars across the face or underneath the pallet rack for visible damage or improper installation a good way to check is to measure the amount of bending or deflection on each beam and replace them as needed.