Palm Oil Storage Tank Cleaning Procedure

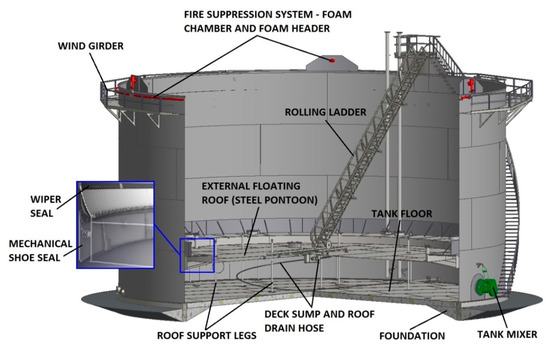

Storage tank cleaning procedure.

Palm oil storage tank cleaning procedure. Like other edible oils palm oil is easily digested absorbed and healthy. It is useful for temporary storage of crude palm oil. Exclude oil stored in the storage tank. Palm oil is an important ingredient in fat mild property is a good material for making food.

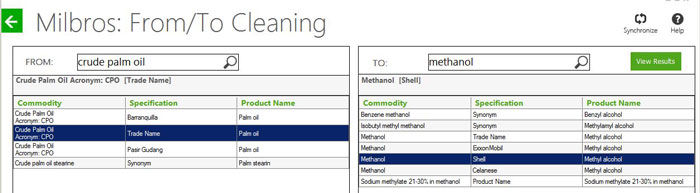

Oil tank cleaning procedure for dry cleaning method. Oil storage tank is mainly used as a crude palm oil cpo storage tank during palm oil process. Grato 50 for stainless steel tanks and grato 14 for zinc epoxy coated tanks. The underground storage tanks usts are preferred by gas.

Large palm oil mill project is designed with a tank for storage crude palm oil after clarification process before dispatch from the mill. And measure the oil tank to ensure that the concentration of oil and gas within a safe range. To carry clean ballast. Now let s talk about oil tank cleaning procedure for each of these four methods.

Any of these chemicals are good for cleaning the palm oil tanks. Generally they store the products in underground or above ground storage tanks. To remove sediments from tank top plating. Cleaning guidelines for drying and semi drying oils.

Aboveground storage tanks asts can be up to 300 feet in diameter and usually contain between 500 000 to 12 million gallons. Palm oil is widely used in the world for cooking and food manufacturing. General tank cleaning procedure. Tank cleaning is the process of removing hydrocarbon vapors liquids or residues from cargo tanks onboard a tanker.

Tank cleaning may be required for one or more of the following reasons. Ventilate the oil tank to exclude the gas and oil in the tank. I guess it would be wise to hire a storage tank cleaning service to make sure the tank is thoroughly cleaned and has no remaining residue of the crude oil. It is used as edible oil crispy fat and margarine.

Industrial plants store water and chemical liquids in huge storage tanks. Inspect the tank to determine if further cleaning is required. If further cleaning is necessary then discuss further cleaning method s with the ship operator. It guarantees a certain storage temperature and good sealing.

If the inspection reveals the tank is clean then carry out fresh water washing rinsing the tank.